- Description

- Technical specifications

- Main characteristics Strong points of the machine

- Use / Examples

- Documents / Downloads

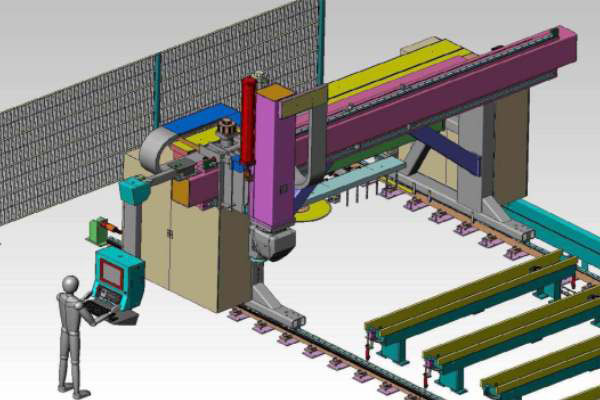

3,4 and 5 axis numerically controlled machining centres for parts in Wood and derivativess

Material

- Wood

Applications

- Automatic 3, 4 or 5 axis centres designed for milling large dimension wooden panels and parts

- Milling, cutting, drilling, profiling, grooving

Allowable part dimensions:

- Length (X axis): 5,000 to 20,000 mm (other lengths on request)

- Width (Y axis): 3,000 x 5,000 mm

- Height (Z axis): 200 mm (other thicknesses on request)

- 3, 4 or 5 axis numerical control centre with moving gantry and fixed working table

- Designed for work on parts in Wood and derivatives

- Large capacity working table, smooth table, grooved vacuum table or 3,000 mm width bridges fixed to the ground, on which parts up to 200 x 3,000 x 20,000 mm can be placed as standard and greater on request

- Parts fixed by stops, clamps, or suction cups and vacuum pumps

- Large choice of spindles from 12 to 30 kW 6,800 to 24,000 rev/min direct mounting (3 axis) or on 4 or 5 axis wrist joint with automatic tool changer, 12, 16 or 24 tool magazine(s)

- Allows cutting out operations for beams, surfacing by milling cutter or planing, drilling / milling / profiling / mortising on composite axes, or even sawing

- Meets the needs of users who are seeking both high machining capacities, versatility and increased working accuracy

- Varied applications: wooden structures, frames, ply adhesive or Kerto structures, concrete formwork, lorry flooring, railway sleepers, engineering structures…

- High accuracy +/- 0.2 mm per linear metre as standard or overall with calibration

- Automatic programming post-processor with batch file and or 2/3D model import as option